Definition of a Cleanroom

As stated in the definition of standard EN 13241, a cleanroom is a “room in which the concentration of airborne particles is controlled."

It is constructed and used in such a way as to minimize the introduction, generation, and retention of particles inside the room, and in which other relevant parameters such as temperature, humidity, and pressure are controlled as required.

Ba2i Systems

- An innovative, dedicated design unlike any other door on this market segment.

- Materials widely used and recognized in the pharmaceutical industry.

- New, clean, and sleek shapes designed without retention zones, minimizing sharp angles in favor of rounded and sloped forms.

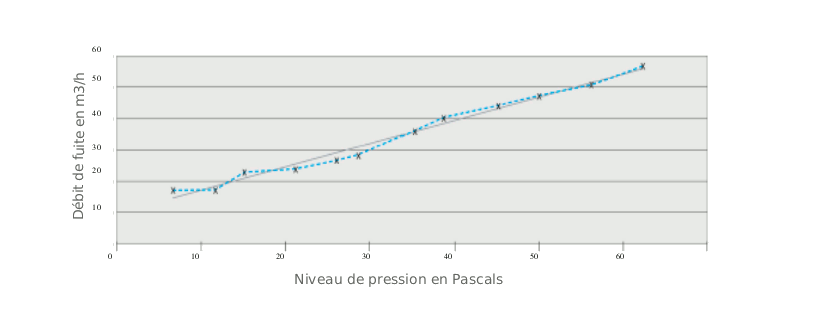

- Full compliance with pharmaceutical environment requirements regarding cleaning, maintenance, and controlled leakage rate.

Cleanroom Industry

Ba2i covers all cleanroom-related industries:

- Pharmaceutical & Parapharmaceutical

- Chemical

- Cosmetic

- Precision Engineering (e.g., Aeronautics)

- Electronics and Micromechanics

- Food Industry

Cleanroom Door Range

Our solutions are fully interoperable. They allow simple or complex interlocking and provide interfaces with cleanroom systems such as HVAC.

Our Cleanroom Door range is extensive and meets all levels of the EN 13241 standard, from ISO 7 and 8.

- Profil Labo

- Profil PI ATEX/Frontier

- Profile PX

Flexible Door for Laboratory

The flexible doors for your laboratory have been fully designed and developed by the Ba2i Technologies design office in close collaboration with our clients. Ba-Labo is the ultimate opening/closing solution for cleanrooms. Our solution already equips major pharmaceutical companies across Europe.

Innovative Design:

The self-supporting monobloc system in painted steel or stainless steel adapts to all types of cleanroom partitions.

The choice of stainless steel, a noble and recognized material in clean environments, guarantees the door’s robustness and reliability.

Simplified Adjustments

The controls positioned on the uprights as requested limit the need for wall-mounted peripherals. Mechanical limit switches ensure simplicity, autonomy, and independence.

The control board is fully programmable, and we adapt it precisely to your use. Everything is designed to make operation easier for you.

Efficient and Quick Maintenance:

There are no dust retention areas. The surfaces are smooth and flush, allowing simple and quick cleaning of the system. The flexibility and resilience of the stiffeners ensure good impact absorption. Access to the electrical box is front-facing on one of the uprights, at human height. These advantages are complemented by a very competitive price positioning.

High-Performance Leakage Rate

Efficient and Fast Maintenance

There are no dust retention areas. The surfaces are smooth and flush, allowing simple and quick cleaning of the system. Moreover, the flexibility and resilience of the stiffeners ensure good impact absorption. Finally, access to the electrical box is front-facing on one of the uprights, at human height.

These advantages are complemented by a very competitive price positioning.